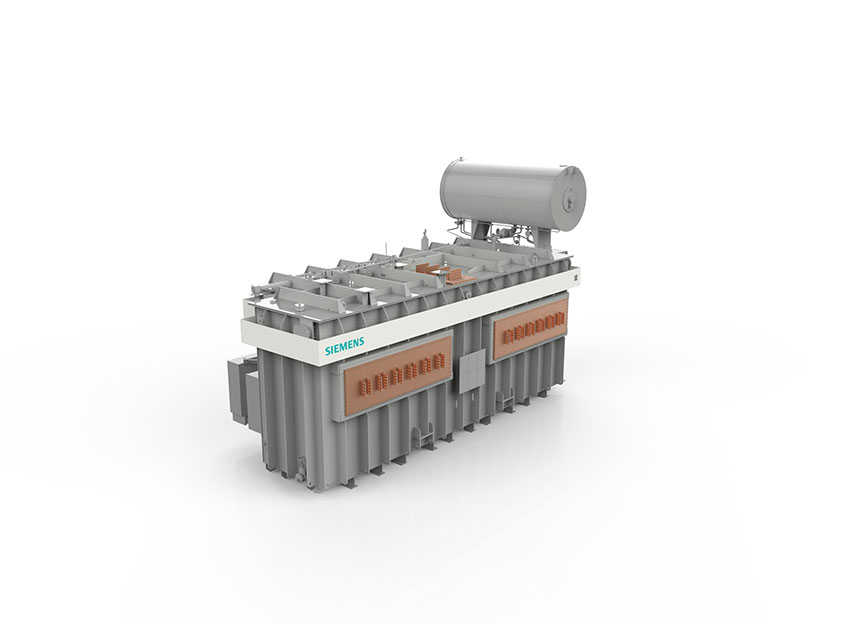

With their reliability, low losses, and maintenance-friendly designs, Siemens Transformers sets standards in cost efficiency.

Tailor-made and designed to withstand the harshest conditions, Siemens transformers provide power for industrial applications, in which current itself is a major resource – from steel manufacturing to electrolysis, from mining to offshore oil and gas platforms. Reliability and cost effectiveness are the main requirements to modern converter transformers. Find out in our exclusive whitepaper how you can specify your converter transformers to enhance your system stability while saving costs at the same time. If you operate furnace transformers you might be interested in learning what measures can be taken to further increase the reliability and lifetime of your transformers. Please find our whitepaper below.

Description

Top performance meets superior environmental and safety standards

Furnace transformers as well as heavy-duty rectifier and converter transformers connect processes to the power grid. Their purpose is to supply a critical resource to energy-intensive industrial applications – high currents with very specific voltages. These transformers must meet rigorous requirements. Siemens ‘ expertise in design and precision manufacturing ensures customers enjoy top performance and efficiency in terms of both cost and energy. At the same time, units need to be extremely reliable in operation and environmentally sound while affording the highest level of safety for those working in their vicinity.

Heavy-duty powerhouses that withstand harshest ambient conditions

Siemens transformers are leveraged in very different environments, from mining to oil and gas extraction, from steel plants to chemical industries. Each area of application requires specific transformer designs to supply the right kind of power for very specific projects in very specific environments. Siemens transformers for all industrial environments. Their especially rugged designs withstand exposure to dirt, gases, short circuit forces, and high magnetic fields.

Siemens transformers built for industrial applications deliver extended voltage regulation ranges. They can provide extremely high currents and have the capacity to feed multi-pulse rectifier units to ensure low system perturbation. This allows them to withstand cyclic load and high thermal stress while remaining highly reliable. In addition, furnace transformers withstand frequent overcurrent and overvoltage caused by short circuits in the furnace or by tripped high-voltage circuit breakers.

Customizability

Rich customization options and unique designs

Siemens Transformers translates individual customer requirements into unique premium-quality transformers with a reputation for superior reliability and an impressive service life. Siemens has developed a wide range of design options to ensure its tailor-made transformers cover all customer use cases.

Design options for high-current transformers for industrial applications

Specifications for voltage, power rating, ambient climate, network topography, and noise level are typical transformer criteria. Further design options include:

- Cooling and extreme-heat protection

- Oil-directed cooling designs for high power densities in small installation places

- Transducers – rugged technical designs for voltage regulation as an alternative to electrical parts

- Defined earthing and electrical grounding to avoid loop currents

- Direct or indirect voltage regulation

- On-load or off-load tap changer

- Compensated lead connection designs to decrease magnetic fields

- Shielding designs to decrease the effects of high magnetic fields

- Monitoring

Monitoring

Protect your transformer assets

Siemens Transformer Online Monitoring System transforms service into reliability

The impact of transformer outages on the process industries in which they are used can be severe because outage costs may not be limited to the cost of transformer repairs. In industrial applications, an outage may result in standstills and a total loss of production. Related costs can quickly rise to a level that affects even larger organizations. An effective way to minimize this risk is the continuous monitoring of key parameters during transformer operation. According to an independent study, online monitoring systems can detect 60% of all typical transformer errors before they occur.

The 5 top benefits of the Siemens TDCM sensor

- Evaluate and time replacements with better accuracy

- Identify incipient faults and take action to avoid costs of a high-impact failures

- Potentially reduce of insurance indemnity for defects

- Gain a better understanding of operative conditions and control to further decrease costs and the risks of faults

- Benefit from predictive maintenance and optimize the maintenance process

Benefits of Siemens Transformer Online Monitoring System

The Siemens online monitoring system for transformers incorporates the most advanced analytical technologies. It helps to effectively reduce failure risks while increasing the efficiency of maintenance during operation.

Replacement

Remanufacturing transformer originals

When a transformer reaches the end of its lifecycle, it needs to be replaced to maintain the operation. Although there are ways to fast-track replacements, ordering, designing, building and even delivering a replacement transformer generally requires careful planning well ahead of its installation. Siemens experts work closely with customers to reliably remanufacture transformer originals. Customer can choose a 1:1 replica or opt for a new transformer that fits into the existing vault or chamber but offers greater capacity.

Same dimensions, higher power density

In steelworks especially, the notoriously small transformer chambers set challenging limits for capacity expansion. Thanks to extensive expertise in cooling designs and in handling high magnetic fields, Siemens is able to offer higher power density with much smaller real estate requirements than the competition.

Standards

Standards

The factory acceptance test, which Siemens transformers undergo fully assembled in Siemens own test bays, includes tests against standards specified by the customer.

These standards include but are not limited to:

- ISO 9001, 14001 for certified plants

- The certification according ISO 29001, a standard important for customers in the oil and gas industry, is a unique advantage of the Siemens transformer production site in Dresden.

- IEC 60076-1 for power transformers

- IEC 61378-1 for converter transformers and as an additional standard for transformers for industrial applications

- IEEE Std C57.12 is a standard for general requirements for liquid-immersed distribution, power, and regulating transformers

- IEEE Std C57.17 describes the electrical characteristics and mechanical requirements for arc furnace transformers. This is a standard relevant to customers located in the US.